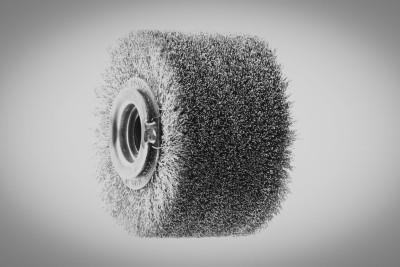

The Brushing treatment by Be.Ro Galvanica is mechanically performed by means of special abrasive brushes, which can remove the defects on the materials, thus producing a satin-finished surface and giving it a semi-gloss and matte effect.

Another very effective and interesting after-treatment processing is Burnishing.

It consists of metal surface colouring, aimed at providing the object with protection against oxidation and improving its appearance.

Galvanic Burnishing in short

The object to be processed is immersed in an aqueous solution of sodium thioantimoniate (or “Schlippe’s salt”) and anhydrous sodium carbonate. At this point the object is exposed to electrolysis for a few minutes at room temperature at 0.35 amps current with voltage ranging from 2.4 to 4 volts.

This method is also used in copper and brass treatment.